An unmet and fast-growing demand

HPCI Green Pellet® solves all the current problems of biomass to make it competitive with coal and oil. Its potential is immense.

The EU and the US have committed to reducing their carbon emissions by more than 50% by 2030, and China is aiming for carbon neutrality by 2060. The price of a ton of CO2 increased by 50% in 2021 and will probably reach €100 in 2022. Renewable energy is becoming increasingly competitive.

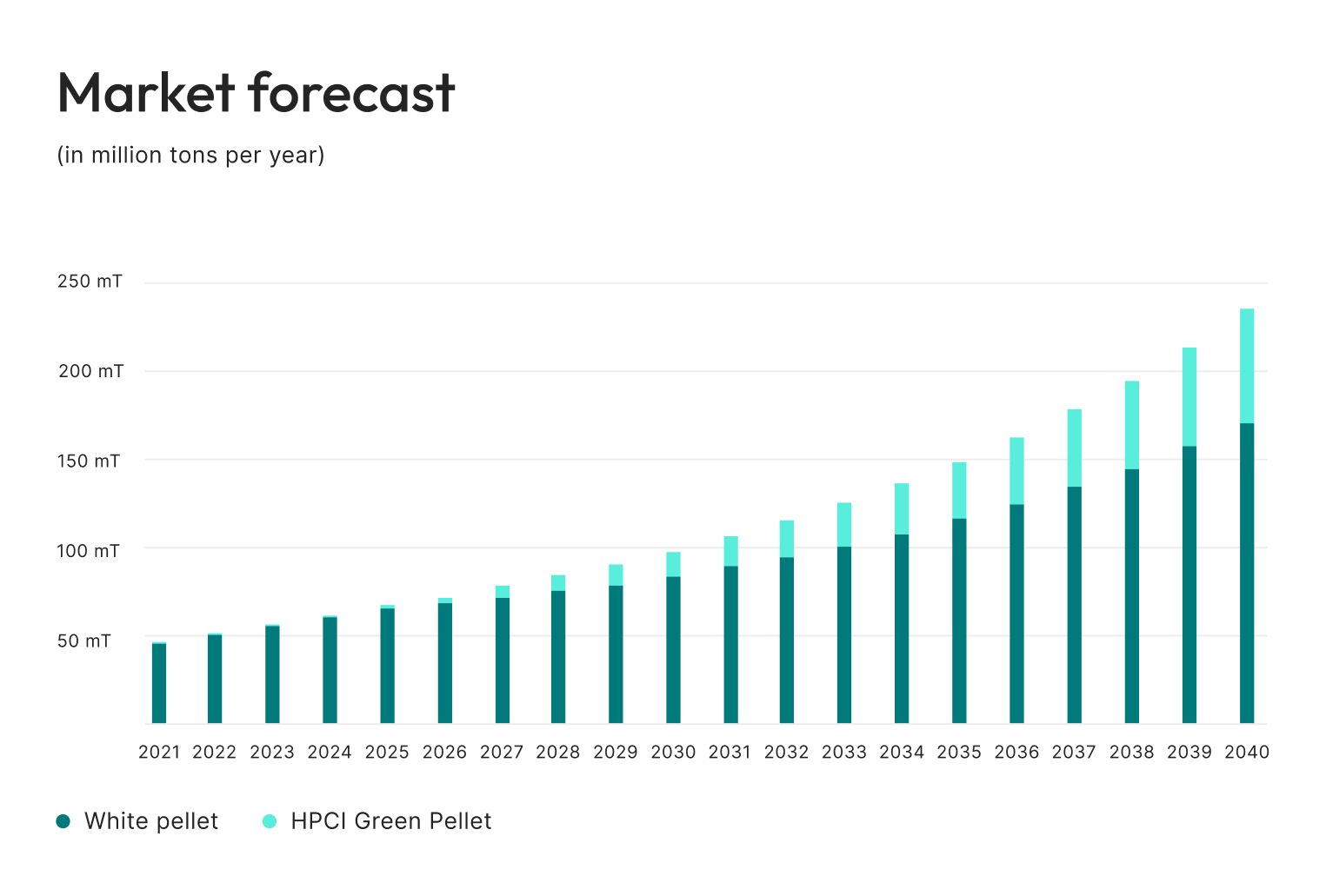

Fossil fuels account for 81% of the world’s energy and must be replaced by 2050. In the meantime, global energy consumption will increase by almost 50%. 23,000 million tons of oil equivalent (Mtoe) of renewable energy will have to be produced. Biomass, which already provides 57% of the world’s renewable energy, is the only non-intermittent energy source to meet this energy crisis.

Unprocessed biomass is uneconomical, has low density and is difficult to transport. White pellets have not solved the problems of moisture and rotting during storage, emission of cancerigenous and explosive dust during transport, and mainly use only one type of biomass: softwood.

HPCI Green Pellet® solves all the current problems of biomass to make it competitive with coal and oil. Its potential is immense.

• Biomass qualification: access to our global biomass observatory (database of characteristics, laboratory tests and trials).

• Adaptation of the process to the project’s biomass and guarantee of the quality of the finished product

• HPCI Green Pellet® plant basic design book

• Return of experience on projects, suppliers, equipment

• Detailed business plan certified by an internationally recognised financial engineering firm

• Analysis of supplies and their sustainability, audit of technologies and off-take

• Network (procurement, engineering, OEMs and manufacturers, industrial customers, financiers)

• Electronic project document management and secure data room on Block Chain

• Task Force involved in the industrial start-up

• Implementation of the Open-HPCI® ERP

• Training and knowledge transfer

• Production monitoring: sensors, Artificial Intelligence and reliability engineers compare your production to that of other factories (best practices)

• Technological progress (continuous improvement of the whole process)

• Biomass or waste opportunities: new biomass, sick wood, B wood

• Process extension: extraction of molecules of interest, applications in biochemistry, biomaterials, biofuels

• The Open-HPCI® ERP covers all operational processes of the HPCI Green Pellet® plant (procurement, logistics, production, inventory, finance, quality)

• The freedom to use Edb-HPCI® Technology

• The HPCI Green Pellet® brand

1. A team of experts and engineers who, after 10 years of research and development, created the Edb-HPCI® dry biomass continuous steam cracking technology, and designed FICAP, the world’s first HPCI Green Pellets® plant

2. The Global Biomass Observatory, a database of detailed characteristics (supply, physico-chemical characteristics) of more than 100 biomasses including field crop residues (wheat, wood, rape, cotton, rice)

3. A laboratory and an industrial pilot equipped with grinding, drying, steam cracking, granulation, and storage tools, capable of testing the biomasses of your project.

4. 350 industrial-scale steam cracking and pelletising tests

5. The Open-HPCI® ERP that covers the entire plant

Our core business

Européenne de Biomasse, creator of the Edb-HPCI® process for converting biomass residues into HPCI Green Pellet®, is a key partner for developers and investors.

We accelerate infrastructure development, maximise profitability and reduce risk by providing expertise at all stages

1. Project development, due diligence and financial closing

2. Construction and industrial start-up

3. Operations

Our core business

Européenne de Biomasse, creator of the Edb-HPCI® process for converting biomass residues into HPCI Green Pellet®, is a key partner for developers and investors.

We accelerate infrastructure development, maximise profitability and reduce risk by providing expertise at all stages

1. Project development, due diligence and financial closing

2. Construction and industrial start-up

3. Operations

• Biomass qualification: access to our global biomass observatory (database of characteristics, laboratory tests and trials).

• Adaptation of the process to the project’s biomass and guarantee of the quality of the finished product

• HPCI Green Pellet® plant basic design book

• Return of experience on projects, suppliers, equipment

• Detailed business plan certified by an internationally recognised financial engineering firm

• Analysis of supplies and their sustainability, audit of technologies and off-take

• Network (procurement, engineering, OEMs and manufacturers, industrial customers, financiers)

• Electronic project document management and secure data room on Block Chain

• Task Force involved in the industrial start-up

• Implementation of the Open-HPCI® ERP

• Training and knowledge transfer

• Production monitoring: sensors, Artificial Intelligence and reliability engineers compare your production to that of other factories (best practices)

• Technological progress (continuous improvement of the whole process)

• Biomass or waste opportunities: new biomass, sick wood, B wood

• Process extension: extraction of molecules of interest, applications in biochemistry, biomaterials, biofuels

• The Open-HPCI® ERP covers all operational processes of the HPCI Green Pellet® plant (procurement, logistics, production, inventory, finance, quality)

• The freedom to use Edb-HPCI® Technology

• The HPCI Green Pellet® brand

1. A team of experts and engineers who, after 10 years of research and development, created the Edb-HPCI® dry biomass continuous steam cracking technology, and designed FICAP, the world’s first HPCI Green Pellets® plant

2. The Global Biomass Observatory, a database of detailed characteristics (supply, physico-chemical characteristics) of more than 100 biomasses including field crop residues (wheat, wood, rape, cotton, rice)

3. A laboratory and an industrial pilot equipped with grinding, drying, steam cracking, granulation, and storage tools, capable of testing the biomasses of your project.

4. 350 industrial-scale steam cracking and pelletising tests

5. The Open-HPCI® ERP that covers the entire plant

Case studies

The potential of HPCI Green Pellet® is global

Japan

Using agricultural residues instead of palm oil

Poland

Close the mines and preserve rural jobs

China

Reducing GHG emissions by recovering waste from rural areas

United States

Reducing GHG emissions and logistics costs

Interested in finding out more?

For more detailed documentation, please contact us.